Shackle & snap hook

Shackles are small helpers that are indispensable in water sports. They must withstand, despite their small size of a very high load. They find extremely diverse applications and are indispensable on boats. Therefore it is very important to pay attention to first-class materials and high-quality workmanship.

Shackles are U-shaped metal shackles, which are operated with a plug-in or screw bolt. Snap hooks have a snap closure with spring support. They can be used to firmly connect different parts and yet easily separate them again. They are primarily used to absorb tensile forces when transferring ropes, chains or wire ropes to other fixed components. For this purpose, shackles are usually secured with cotter pins or nuts. They are usually made made of stainless steel, steel or bronze and are available in various designs. Their curved shape makes the connection more flexible. The manufacturing processes used are forging and gritting.

Use of shackles on boat

Shackles can be found almost everywhere on boats, regardless of whether it is a small dinghy or a luxury trimaran. The aids must withstand very high loads anyway, and weather influences such as wind and rain are also added. Shackles must therefore be corrosion-resistant and, depending on the area of application and the corresponding design, withstand a high load. Shackles, for example, provide support for the stays at the bow, stern and top, strengthen the blocks at the base of the mast and connect the mainsheet buoy. Bending or breaking of the metal shackles poses a considerable danger. Therefore, high quality shackles should be used on the one hand, and on the other hand, care should be taken to ensure that an attached Version of the shackle is used.

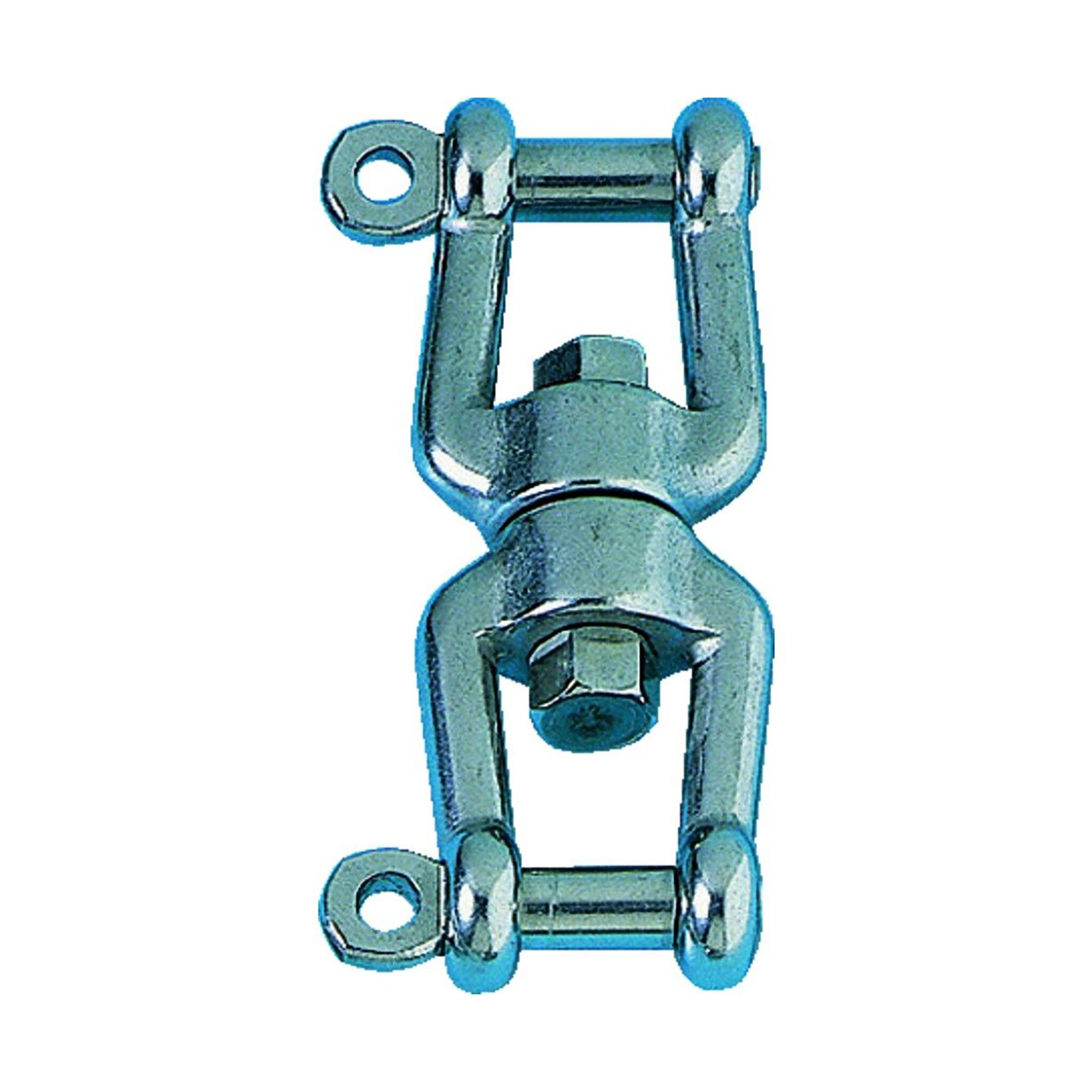

Different shackle designs

Shackles are available in different designs and sizes, each suitable for different purposes. For example, shackles with eyebolts are mostly used for temporary purposes, while shackles with nuts and cotter pins are used for long-term and permanent applications. The latter also serve purposes where the pin could rotate around due to a load.

Rope shackle

Tew shackles, unlike conventional shackles, are made of braided rope or synthetic or natural fibers. This usually involves splicing an eye to the end of a short length of line and tying a diamond knot to the other end

Patent shackle

Patent shackles do not have a threaded pin that is closed with a shackle to flap, making them very quick to use. They are opened by a spring pin and closed by a snap shut. Sprenger produces in Germany mainsheet blocks with clamp, dog shackle and swivel. The patent shackle used in this process allows for quick operation.

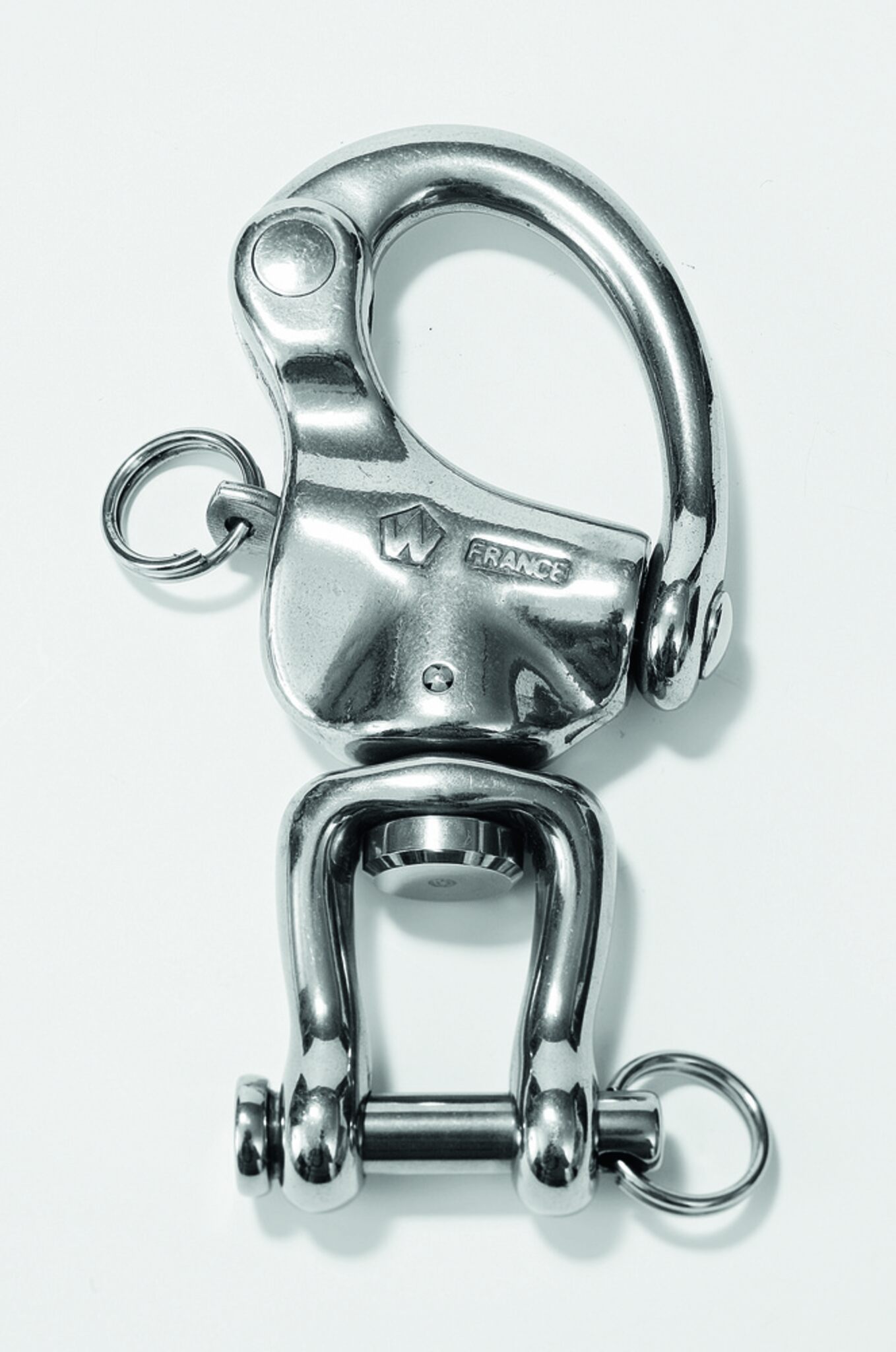

Fall shackle / snap shackle

Fall shackles, also known as snap shackles, are opened opened by a spring pin and closed by a snap. There are variants with a swivel eye or with a fixed eye. In addition, the shackles can have a side or top opening. Swivel snap shackles often have additional rings or a swivel eye that is ring-shaped. High-quality snap shackles are used, for example, on halyards, because enormous forces are transmitted during sail setting. are transmitted. Wichard shackles, for example, are made of high-strength stainless steel and have a plastic coating that ensures less wear on the ropes.